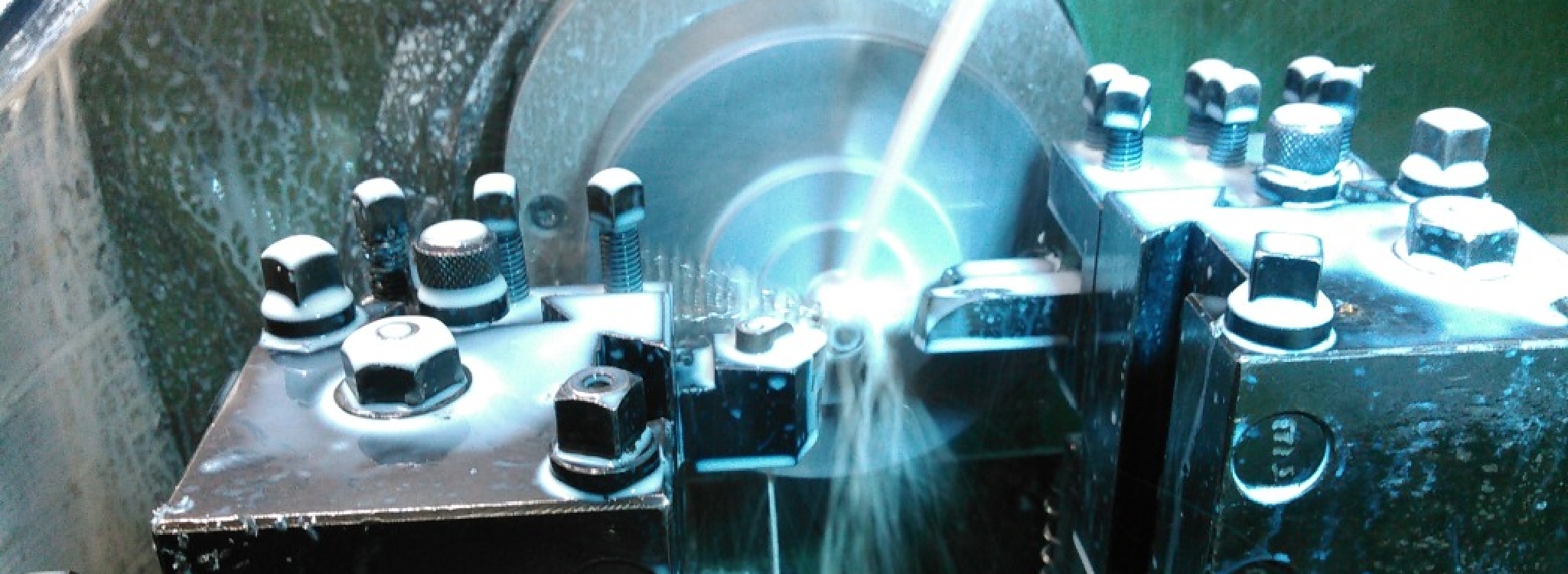

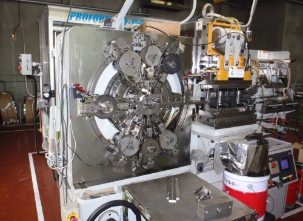

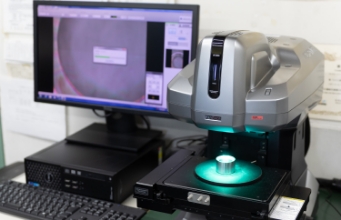

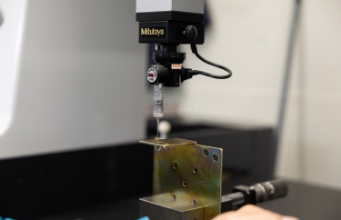

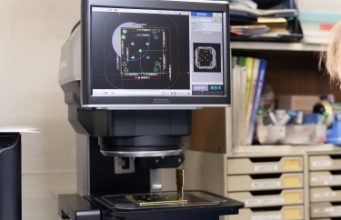

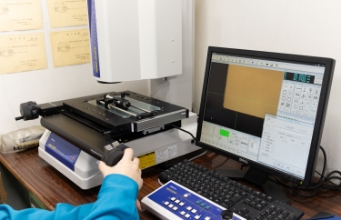

Ooyama has more than 2,000 partner companies nationwide, allowing us to handle all kinds of shapes, materials, and processing methods. We also have a full range of inspection equipment, and have established a system that allows us to deliver high-quality products at all times.